With our State-of-the-Art technology and continuous product innovation, we have provided diversified FR products and established long-term relationships with global technological partners. We have more than 30 patents filed making us a global technological leader.

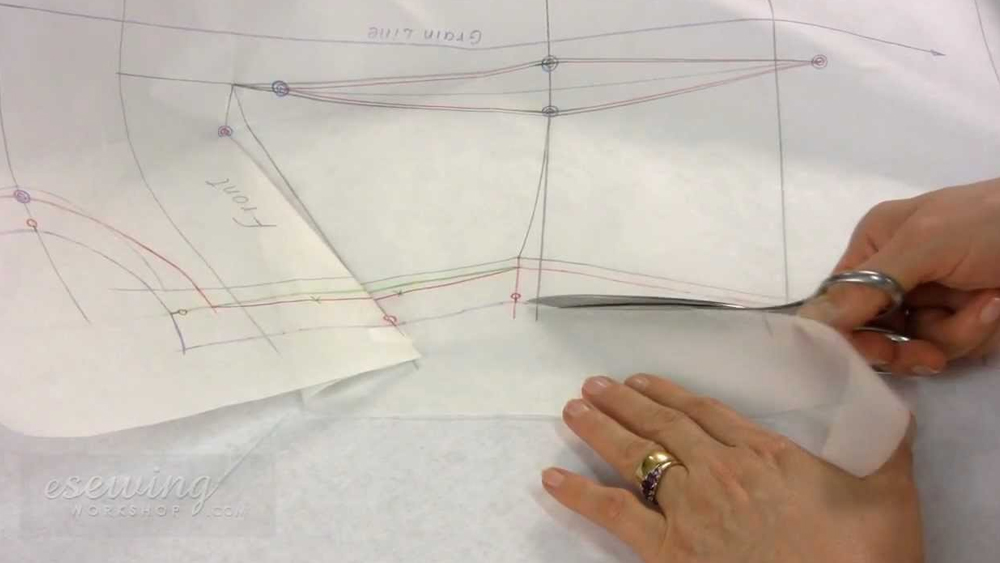

From spinning to garmenting & fibre to performance, our world class infrastructure facility is key to manufacturing high-quality FR products. We are an end-to-end player in the protective market industry.

Having worked closely with many customers globally, we have garnered considerable finesse in developing and perfecting fine-tuned FR solutions in challenging situations. With customization of product colour, pattern, material and accessories, we keep customer satisfaction on high priority.

Our in-house PU bi-layer & tri-layer lamination process provides a barrier against wind, water, chemicals, microbes and harmful vapours present in the environment while allowing perspiration to escape and maintaining fabric stretch ability. Consequently, providing enhanced protection and increasing life of the FR garment.

With a highly qualified team of R&D engineers and employees, we manufacture 10 million metres of Flame Retardant fabric annually. Our strong market research and trend analysis is the key to a strong industry foothold and diverse product range.

With our State-of-the-Art technology and continuous product innovation, we have provided diversified FR products and established long-term relationships with global technological partners. We have more than 30 patents filed making us a global technological leader.

From spinning to garmenting & fibre to performance, our world class infrastructure facility is key to manufacturing high-quality FR products. We are an end-to-end player in the protective market industry.

Having worked closely with many customers globally, we have garnered considerable finesse in developing and perfecting fine-tuned FR solutions in challenging situations. With customization of product colour, pattern, material and accessories, we keep customer satisfaction on high priority.

Our in-house PU bi-layer & tri-layer lamination process provides a barrier against wind, water, chemicals, microbes and harmful vapours present in the environment while allowing perspiration to escape and maintaining fabric stretch ability. Consequently, providing enhanced protection and increasing life of the FR garment.

Our strategically placed production units enable the customer to buy our products from wherever logistically convenient to their business operations. With a strong foundation of knowledge and research, we identify the market needs to ensure quick worldwide delivery.

With a highly qualified team of R&D engineers and employees, we manufacture 10 million metres of Flame Retardant fabric annually. Our strong market research and trend analysis is the key to a strong industry foothold and diverse product range.

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/